An Adventure With A High Contrast Black Walnut Branch (or Sometimes You Get Lucky)

A buddy brought me three freshly cut branches of walnut - two of Black Walnut and one of English Walnut. IN orchard country - which Silly Cone Valley was at one time - Black Walnut branches are somewhat rare. They'd graft English Walnut onto a Black Walnut roots and trunk, creating a very hardy tree and yet still get marketable sized and tastier walnuts in quantities worth harvesting.

About 6 inches in diameter - with the bark and some moss still on them - and about 14 inches long, they were perfect for turning on my JET midi-lathe. Bandsawed the ends parallel and close to square to the length, popped a spur drive in the head stock , a live center in the tail stock and fiddled with the balance until it was ready to turn. Sharpened the roughing gouge, set the tool rest, cranked the lathe speed to it's lowest rpms - 500 and turned the lathe on, finger kept on the switch just in case. I got lucky - important if you're playing with a midi-lathe, sitting on the worbench top - on a thin rubber pad.

Steady the roughing gouge on the tool rest almost vertical, got a good grip on the handle, tucked agains my leg, left hand touching the tool rest and gripping the gouge, eased the bevel into the most out of round spot. Small pieces of bark started shooting off the cutting edge as it clunked in it's right to left then left to right arc. In five minutes I looked like a negative of the Abominable Snowman. But the piece was coming round and the clunking began subsiding.

Soon short ribbons of the cambium layer started streaming off the gouge and finally long, wider ribbons of sapwood shot off the tool like water out of a fire hose. It was glorious!

But the fun was just beginning.

As you can see, the sapwood is almost white and the heartwood almost black. It was decision time. Go with the original shape I had in mind for this piece or go where the wood led me? Because there were knots which can spread out all over hell as they come out from the center, the black white patterns could change very unpredicably - AND VERY QUICKLY.

I began taking very, very light passes, stopping the lathe after each pass to see what was appearing. A pair of pin knots at one end became visible at the roughed to round stage, with gray hints of others - in a cluster. A few more tapering towards the pin knots passes revealed more small dark heartwood pin knots surrounded by white sapwood, along with heartwood opposite them. From that point on, any pre-planned form was abandonded and the wood dictated what would happen next.

From that point on it became a Zen thing, the tool and the wood played together, with me along for the ride. Time stopped, the shop disappeared. Only the spinning wood, the the tool and this amazed audience of one remained. Everything was just so -effortless, perfect, doing just what each was supposed to be doing - at that moment. The echoes of such moments linger for a long time and thus provide encouragement to continue playing with wood - perhaps to return to that place referred to as suchness.

And here's where the wood said "STOP!"

An inch and a half forstner bit, an extension, a jacobs chuck in the tail stock and a lot of "bore some, clean out the hole, bore some more, clean out the hole ... and I'd created my first semi-real hollow vessel. Now if I can just work up the nerve to poke a goude inside the hole and thin the wall down . . .

"I'm ready for my close up Mr. DeMille."

(sanded to 400, burnished with shavings and 10 coats of paste floor wax -it's actually about 25 percent larger than this picture"

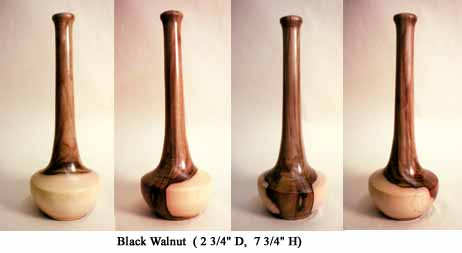

Here's another one from a fresh cut black walnut branch. About two thirds of this branch, was the white sapwood. I knew that once given a half dozen coats of carnuba wax,, the sapwood would stay almost ivory white. I decided to go for a white base and a long thin neck of the dark heartwood. The look of the piece changes significanlty as it's rotated, but remains interesting regardless of the viewer's position.