In order to get to the arpicot tree that needed to be cut back because it was leaning on the shop roof which caused water to leak on my router table . . . (that Jack built), I had to cut back the shag bark melaleuca (in the bottle brush family).which was getting in the way. (Often times one must do EVERYTHING in order to do ANYTHING). Some of the cuttings were of turning diameter and the wood looked fine grained and almost white.

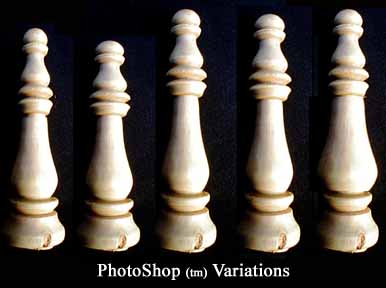

SO - since I'd already roughed to round all the pieces of fresh cut apricot I figured I'd try turning some "green" melaleuca . Turns nicely and I got a lot more practice with a skew chisel. The diameter was perfect for trying to turn a chess piece - a bishop specifically. Been a while since I played chess, or saw a bishop, but I think I got the basics. The proportions on the other hand - well they were close, but somehow not right. So I took a digital picture, got into Adobe PhotoShop (tm) and did variations. The piece in the middle is the original bishop I turned, It's a lot easier to stretch, squash and deform an image than it is to turn a bunch of variations. I've used PhotoShop (tm) for working out furniture variations but it will come in even handier with turnings. Much easier to visualize things than with just a line/CAD drawing since it has shading AND can be done very quickly - no rendering time.

If you have PhotoShop (tm) or any other graphics program that'll let you "stretch" all or part of an image you may find this useful in your design work.

Had a short, maybe four plus inch long melaleuca leftover from the above chess piece and decided to see how small I could turn something. Should've parted off the little ball end but decided to cut down the base end first. BIG mistake. Was using a STEBCENTER that has a spring loaded pin. The spring is pretty strong. The idea is that if a catch occurs the spring will push the piece away from the teeth on it and let the piece spring free rather than get gouged out. Now add a thin green turning and a little drag on the free center. The big end gets slowed down, the drive end doesn't, the thin green wood twists and the spring loaded pin in the STEB CENTER pushes. The weakest point twists then bends and tears. Bummer. But I know what I did wrong so the experiment was worth it.