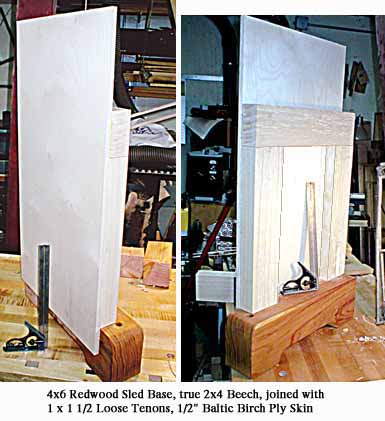

Here is one of the sides - without the inside ply skin. The uprights were positioned so that the outside ply skin could be glued to the outside of the sled leg base. They're loose tenoned together and loose tenoned to the sled leg / base.

You may be wondering why the outside ply skin sticks up so high. I'm going to run All Thread in dadoes in the bottom of the 4x12 top and through the ply sides to secure the top to the sides. The sides will stick up about 4" above the bench top - to keep tools on the bench - and to contain some of the copious quantities of chips and shavings that a lathe generates.

Now does it make more sense?

If you look closely at the above photo, you'll notice that there are round dogholes in the arpon of the bench as well as on the side of the end vise. They come in handy for all sorts of things. In this case I'm dry fitting the top and the sides of this "in progress" lathe bench. The top is pretty heavy and requires both hands. I want to set the top down on the left side of the bench and move the right side in to snug against the bench top. A long dog in the bench apron keeps the left side of this bench from falling over. Another in the end of the end vise holds the right side semi-upright and lets me move it in to the bench top. At that point I can Bessy or pipe clamp the sides to the bench top and "slip stick" the distance between the insides of the sides to get my stretcher length. (click here for Slip Sticks).

With the top and sides together, temporarily, I can use a pair of slips sticks and a small spring clamp to hold them together to "measure" the distance between the sides.