Using the Slip Sticks to get the inside length of the rear stretchers, I set a stop on my miter saw and cut the long parts of the rear stretcher torsion box frame. The inside ply had already been ripped to 12 inches wide so they could be cut with the same set up to insure all parts that are supposed to be the same length are the same length. The long parts of the frame were glued to the "inside" 1/2" ply and the short parts of the frame were cut to fit and glued in place.

To add some more weight to the rear of the bench I put 30 pounds of #9 lead shot inside each of the rear stretcher torsion boxes. I could've just put a shelf on the bottom f the bench and added bags of sand - but that would look really ugly and it'd make cleaning up under the bench a PITA. Could've also filled the torsion boxes with sand, but sand isn't as heavy as lead shot - and doesn't look as cool.

When it came to glue the back side of the torsion box stretchers, the advantage of a 24" wide bench starts to show up - when clamping things.

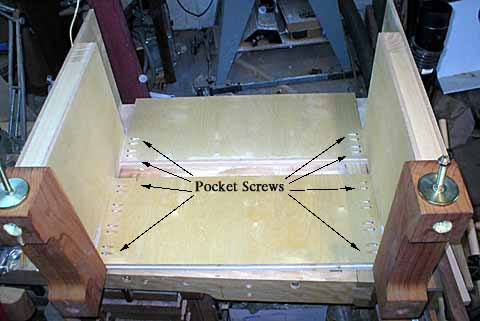

I want the option of making this bench wider should I decide to add a lathe bed extension. So I used pocket screws to join the stetchers to the bench sides, Because the inside skin of the torsion box fits between the bench sides and the outside skin extends out to the outside of the bench sides, it'll be easy to extend the stretcher torion boxes should I need to later.