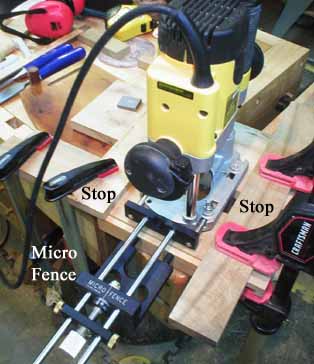

I had A PLAN for cutting the mortises in the top and bottom of the cabinet. Clamp a board whose edges paralled the mortise to be cut, use one edge for the Micro-Fence reference, clamp on some stops and route the mortises. The Micro-Fence would allow me to fine tune the width to fit the knife hinges exactly.

(Note to self: If the hinge is 5/16ths wide use a 5/16ths router bit! Don't waste time going with the quarter inch spiral wih the half inch shank instead of the 5/16ths which only has a quarter inch shank. One set up, one pass provides fewer opportunities to screw up than two or three set ups and passes.)

Question to Brusso: Why not put a 5/16ths diam, on BOTH ENDS of your straight knife hinge?!?!

Great plan. Bad execution of the plan. There are two knurled knobs that fix one part of the guide to two steel rods attached to the router. Loosen them to move the fence close to where you want them. Tighten them and then loosen another knurled knob to make micro adjustments in thousandths of an inch. The combination lets you get close quickly and then right on very precisely. With everything locked down it's just a matter of some plunge routing. The key to all this though is the "everything locked down" BEFORE the actual routing . The initial pass produced a mortise that was just a tad narrow. Once again - things were going so well. If only I'd locked down the precision adjustment locking knob ...

BTW - if the screws that lock down the Micro Fence connection to the router aren't tightened down enough vibration WILL work one or both loose. When that happens the results are "less than perfect". If there are multiple means of screwing things up I'LL FIND THEM!

So before I can try "the hard part" I've got to figure out how to fix this OOPS!. OR - since it's on the underside of the top of the cabinet where it probably won't be seen - - -

more to come ...