The other axis permits + 40 degrees to - 10 degrees of angle. Being able to do "negative angles" probably will be handy at some point but why isn't clear to me at the moments.

Note the parts with the holes in them. These act as stops for rounded tenons. They can be reversed for make square ended tenons. The holes in the "stops" plates are for dowling though I haven't checked out how to use this capability.

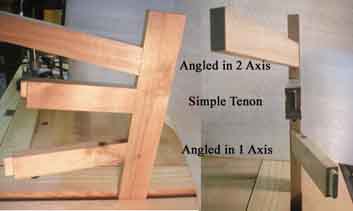

Here are three of the four types shown above. Working out how to get the outside edge of the tenoned piece to line up with the outside edge of the mortise piece is not trivial and required several test tenons.

By rotating the top plate it's possible to do "twisted" tenons - sides not paralleling the faces or edges of the parent part. The range of rotation is limited to perhaps +/- 10 degrees. How that could be used is not apparent - at least not to me,