Resawing (You can do it - honest)

You've found a really nice board that has beautiful grain or a really striking figure - quilted, flame, curly .... You wish you had enough of it (and could afford to buy enough) to make a nice jewelry box out of it, or maybe drawer fronts for a small 3 drawer unit. Alas, you have just this one piece. What to do? What to do?

You'd like to put a nice black walnut panel in the bottom of the jewelry box you're making but you just can't see taking that 3/4 board of pretty walnut down to 1/4 in your planer. It'd be a crime to waste all that precious wood. What to do? What to do?

You'd like the grain on your drawer fronts to run up and down rather than left/right but you know solid wood won't work in that orientation and veneer is expensive. What to do? What to do?

You'd like to do a bookmatched panel in the cabinet door you're making. You found a couple of boards with nice grain - but they don't go together well and you couldn't find two bookmatched boards you liked. What to do? What to do?.

You'd like to get into thin line inlaying to add that missing touch to that special end table you're making. You've got some boards of really nice stuff that would be perfect but how to make thin strips of it without loosing half the material to the saw kerf. What to do, what to do?

The answer to all of the above is - RESAW.

I know, you've seem guys at woodworking shows effortlessly sawing paper thin slices off a 12 x 12 block of solid cherry. You said to yourself "That guy's got years and years of experience, the perfect saw blade, set up just right, the special fence and the perfect piece of wood. I'm sure I could never do that on my bandsaw at home. Someday, maybe some day I'll try that." . But you still haven't tried it and a few years have gone by since you watched that first resaw demo. You've got the bandsaw and you use it in place of a scroll saw, you've cut some thicker stock for some special parts, perhaps cabriolet legs. BUT you've shied away from having a go at resawing.

My hope is that before you click away to some other far corner of the internet you at least leave with the feeling of "I can do that!"

I'm going to assume that you own a bandsaw, know how to set the table square to the blade, know how to set the guides and how to tension the blade. I'm also going to assume that your bandsaw's table is too small.

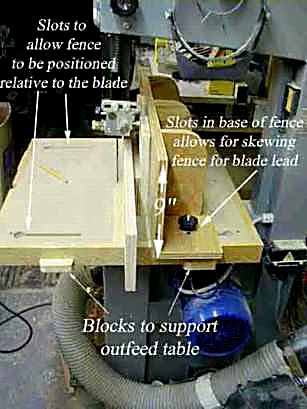

OK, here's the secret. Make a bigger table and. most important, your own Custom Deluxe Wip-Zam Super Duper Adjustable Fence.

It's very rare to have a bandsaw blade set up so that it cuts perfectly square to the front edge of the table. Here's why.

That's why you need a fence than can be adjusted for the blade's lead angle. To find a blade's lead angle, take a piece of stock a foot or so long,. scribe a line on the top and then cut following the line for about 6 inches. Without moving the piece, stop the saw and draw a line on your table using the edge of the board. Remove the wood, move the fence over and set it to the line you just made. Viola, you're ready to start making your own thick veneer, bookmatched pieces etc.

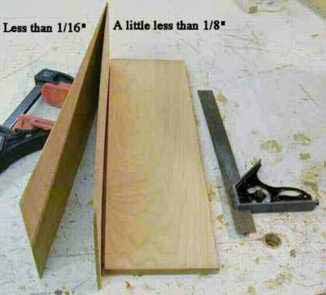

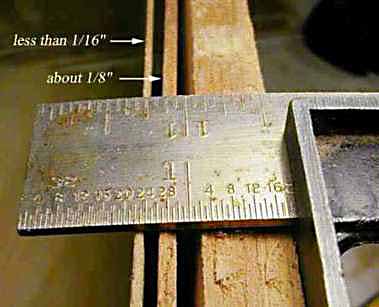

I'd tried resawing with the fence that came with my bandsaw with poor results. Got so discouraged until I built this set up (based on an American Woodworker article). I took these photos after making my first two cuts off a 1x5 piece of cherry - the first being the 1/8 inch slice and the second just to see how thin I could go. I'm sure I can cut even thinner but see no reason to.

Think of that board you've hung on to just because it was so nice but not enough to make anything with. Think of all the precious wood you've turned into sawdust and chips getting it to the thickness you needed for a piece. Think of all those pieces you've admired that had bookmatched panels or drawer faces. Think of the through dovetail jointed drawers you did that would have looked even nicer if you'd been able to do half blind dovetails on the fronts. Do you do marquetry or interasia (sp?) and wish you could make your own thin stock? Wish you could make some inlay stock out of some of the great pieces of wood you've stashed away? Just think of all the possibilities!

If I can do it so can you. Here's the URL for details on the shop built table and resaw fence.

Click here to see more about the new table and resaw fence you can make

here's some details of the table and fence

and then Click here to find out more about sawing and resawing ( American Woodworker)

You can also continue on and how to prepare stock for and do fine line inlaying by clicking here.